machinist@lists.ibiblio.org

Subject: Machinist

List archive

- From: Lawrence London <lfljvenaura@gmail.com>

- To: machinist@lists.ibiblio.org

- Subject: [machinist] 5c collet block?

- Date: Sat, 11 Jan 2014 23:59:20 -0500

http://www.practicalmachinist.com/vb/general/5c-collet-block-278316/

Thread: 5c collet block?

-

01-11-2014, 03:49 PM #1

- Join Date

- Feb 2009

- Location

- Shallowater, Texas

- Posts

- 471

5c collet block?

5c collet block?

I have a job that requires I drill a .070 cross hole in a .375 piece of 360 brass, the job is 120 pieces. Would a 5c collet block held in a vise on my drill press be the most accurate and quickest way to do this job?, I have never used a 5c collet block, I am thinking of buying the block with the lever to speed up this process.

-

-

01-11-2014, 04:20 PM #3

- Join Date

- Feb 2009

- Location

- Shallowater, Texas

- Posts

- 471

-

You will have to spot the hole first. A #50 drill can easily wander off the center of round stock. On a drill press that is more of a job for a finger plate type jig with a drill bushing. Use a toggle clamp with a soft "V" pad to hold the work and mount an end stop to control position.

-

01-11-2014, 05:02 PM #5

- Join Date

- Feb 2009

- Location

- Shallowater, Texas

- Posts

- 471

" finger plate type jig", which i knew what that looked like.

I have some hex stainless steel on hand. i have thought about making one cut lengthwise on a short piece of hex, then drilling it with a .375 drill. then placing the brass inside the hex and clamping it in the vise on the drill press, spot drill first, then drill with a #50 drill bit. how well would that work?

You will have to spot the hole first. A #50 drill can easily wander off the center of round stock. On a drill press that is more of a job for a finger plate type jig with a drill bushing. Use a toggle clamp with a soft "V" pad to hold the work and mount an end stop to control position. -

01-11-2014, 05:21 PM #6

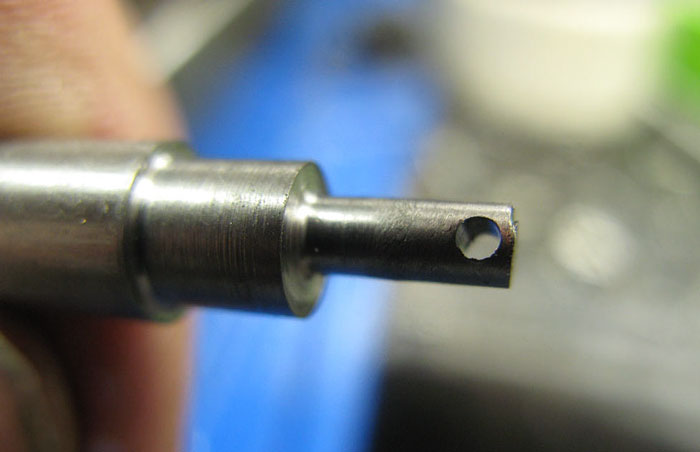

I have a little job where I have to cross drill the turned end (1/8" diameter) of a rod for a 1/16" roll pin. I find the easiest, fastest and most accurate way for me is to drill a hole in a piece of 1/2" square cold rolled steel to accept the rod, with my cross hole lined up and used as a drill jig. Not heat treated or otherwise sophisticated, this little jig has worked for a few thousand holes so far:

The result is good enough for me:

-

01-11-2014, 09:24 PM #7

Length in vise jaws with stop on side of OD ?

-

[machinist] 5c collet block?,

Lawrence London, 01/11/2014

- <Possible follow-up(s)>

- [machinist] 5c collet block?, Lawrence London, 01/12/2014

Archive powered by MHonArc 2.6.24.

Reply

Reply