machinist@lists.ibiblio.org

Subject: Machinist

List archive

- From: Lawrence London <lfljvenaura@gmail.com>

- To: machinist@lists.ibiblio.org

- Subject: [machinist] 5c collet block?

- Date: Sun, 12 Jan 2014 15:43:25 -0500

http://www.practicalmachinist.com/vb/general/5c-collet-block-278316/

Thread: 5c collet block?

-

01-11-2014, 03:49 PM #1

- Join Date

- Feb 2009

- Location

- Shallowater, Texas

- Posts

- 472

5c collet block?

5c collet block?

I have a job that requires I drill a .070 cross hole in a .375 piece of 360 brass, the job is 120 pieces. Would a 5c collet block held in a vise on my drill press be the most accurate and quickest way to do this job?, I have never used a 5c collet block, I am thinking of buying the block with the lever to speed up this process.

-

-

01-11-2014, 04:20 PM #3

- Join Date

- Feb 2009

- Location

- Shallowater, Texas

- Posts

- 472

-

You will have to spot the hole first. A #50 drill can easily wander off the center of round stock. On a drill press that is more of a job for a finger plate type jig with a drill bushing. Use a toggle clamp with a soft "V" pad to hold the work and mount an end stop to control position.

-

01-11-2014, 05:02 PM #5

- Join Date

- Feb 2009

- Location

- Shallowater, Texas

- Posts

- 472

" finger plate type jig", which i knew what that looked like.

I have some hex stainless steel on hand. i have thought about making one cut lengthwise on a short piece of hex, then drilling it with a .375 drill. then placing the brass inside the hex and clamping it in the vise on the drill press, spot drill first, then drill with a #50 drill bit. how well would that work?

You will have to spot the hole first. A #50 drill can easily wander off the center of round stock. On a drill press that is more of a job for a finger plate type jig with a drill bushing. Use a toggle clamp with a soft "V" pad to hold the work and mount an end stop to control position. -

01-11-2014, 05:21 PM #6

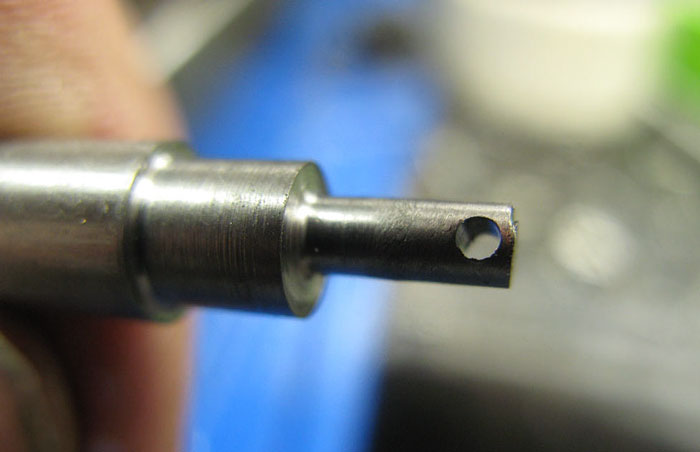

I have a little job where I have to cross drill the turned end (1/8" diameter) of a rod for a 1/16" roll pin. I find the easiest, fastest and most accurate way for me is to drill a hole in a piece of 1/2" square cold rolled steel to accept the rod, with my cross hole lined up and used as a drill jig. Not heat treated or otherwise sophisticated, this little jig has worked for a few thousand holes so far:

The result is good enough for me:

-

01-11-2014, 09:24 PM #7

-

01-12-2014, 01:51 AM #8

- Join Date

- May 2008

- Location

- elmirage ca

- Posts

- 416

Use Franks type of fixture (1x1 x2) block.Drill 3/8 hole thru,cross drill for dowell at the depth you wantThen

drill for the .070 cross hole.leave enough of the brass sticking out to hold it.I use spark plug wire

pliers.Once set up,insert part,drill,remove,do it again.

jim -

01-12-2014, 08:46 AM #9

- Join Date

- Feb 2009

- Location

- Shallowater, Texas

- Posts

- 472

thas exactly what i did!, sometimes I try to "over" complicate simple tasks, i think thats the dyslexia getting in my way.

Use Franks type of fixture (1x1 x2) block.Drill 3/8 hole thru,cross drill for dowell at the depth you wantThen

drill for the .070 cross hole.leave enough of the brass sticking out to hold it.I use spark plug wire

pliers.Once set up,insert part,drill,remove,do it again.

jim -

01-12-2014, 10:54 AM #10

I use press-in drill bushings in fixtures when drilling more than a few hundred holes. Drill Bushings | Precision Bushings | Headless Press Fit P

Don -

If you have a thousand or so parts, look for a used Heinrich 305 cross hole jig. List is $330, but they turn up on eBay. They have a cam clamp to hold the part while drilling.

In any case, you want a split point drill bit to drill into a round part.

Heinrich Company - Hand Operated Cross-Hole Drill Jig - Racine, Wisconsin

Larry -

01-12-2014, 11:31 AM #12

I cross drill using 5C collets first using a spot drill so the drill bit won’t wander. An advantage of holding in a 5C collet vs a fixture with a fixed hole is that other operations can then be performed in the hole just drilled such as tapping in the cross drilled hole such as the 1.063” diameter part held in a 5C collet shown below.

And yes 5C collet blocks can be handy mounted in the vise for cross drilling and indexing when one just does not want to dismount the vise and mount the rotary table.

Don

-

[machinist] 5c collet block?,

Lawrence London, 01/11/2014

- <Possible follow-up(s)>

- [machinist] 5c collet block?, Lawrence London, 01/12/2014

Archive powered by MHonArc 2.6.24.

Reply

Reply