machinist@lists.ibiblio.org

Subject: Machinist

List archive

[machinist] Tried and True Machine - Page 2 innovative shop made tooling and fixturing

- From: Lawrence London <lfljvenaura@gmail.com>

- To: machinist@lists.ibiblio.org

- Subject: [machinist] Tried and True Machine - Page 2 innovative shop made tooling and fixturing

- Date: Tue, 7 Jan 2014 21:26:30 -0500

http://www.practicalmachinist.com/vb/member-shop-photos/tried-true-machine-276464/index2.html

- Join Date

- Apr 2007

- Location

- Pillager, MN

- Posts

- 2,998

I thought I could work in some new stuff with the old. This is a really simple UHMW part I have been doing for years. The vid makes it look easy, but any of you guys who machine any amount of this stuff know it's always a pain. The trick is to get the chip to do what you want it to do. Feed it hard and fast. Light cuts are your enemy.

CNC lathe-plastic - YouTube-

-

12-27-2013, 01:13 PM #27

-

-

12-27-2013, 02:11 PM #29

I'm curious, how many of those is the order for? Are there second/third OPs?

I really like your process on that part.

Also, I am in the market for a bar-puller. What brand is yours? -

It's just a piece of 1 1/2" wide steel banding. Popped a hole in it and bent it. I bend towards or away from the cutoff tool depending on the Ø of the part.

Order size? Well, years ago I would be making anywhere from 500 to 1000 at a crack. Now it's down to 100 or so per order. Its for customer who's product that has run it's course. Set up under 20 mins. OP 1 is around 50 seconds. Set up for OP 2 is around 10 mins. OP 2 is just a boring OP and takes less than 15 sec with load and unload. They go fast. -

12-27-2013, 03:28 PM #31

-

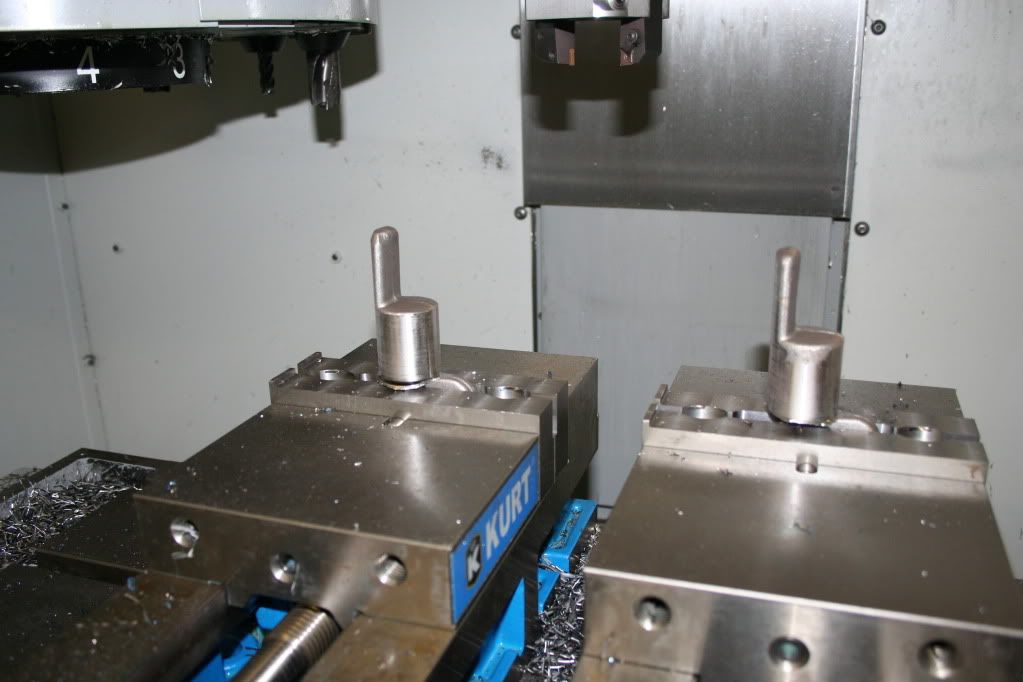

I've posted these pics before, but like all of my past posts with pics, they disappeared. I have been machining these forgings for a few years. They suck. Really suck. But over time you figure out better and faster ways of doing things. Faster and cheaper= less sucking.

They are just a mild steel forging. Dead soft and kind of gummy. Nothing special. I wish they were a medium carbon steel because they would machine nicer. Their odd shape makes them difficult to hold onto. I have to stand them on edge and grip on a narrow tang to qualify the major diameter. Took a while and some trial and error to get it down pat. In the pic you can see the little "stops" sticking up on the left side of the vise jaws. I use a 1-2-3 block standing the 3" way to square the part and locate it left to right.

Now to machine it is another challenge. The part needs to be round. No way to chuck it in the lathe and no way to interpolate it round standing on edge on the pic. (I did try one time. But because of the flimsy tang, it squealed like a stuck pig).

So onto some custom tooling. I made a hollow mill. The first one was just a hunk of round turned down to be clamped in a end mill holder and bored and slotted to accept 3/8 shank brazed carbide turning bits. It worked OK. But it was hard to set the tools, they liked to chip the carbide, and it wasn't all that rigid. I switched to some small inserted tool holders. It solved setting the tools to the correct position, but they were a weak insert, and the lack of rigidity caused the inserts to fail way too often.

I needed something else. After a lil head scratching and some doodles on paper, I came up with a perfect design. Rigid, repeatable, and reliable. And it looks pretty darn cool too. Grabbed a chunk of D2 I had lying around and started whittlin. I used two left hand lathe toolholders with CNMG style inserts. Mounted it to a CAT40 facemill holder. Nice and rigid. I did have play with it a little to get them set to cut the correct diameter. The tolerance on the part is quite wide open (+/-.005). I had to take few test cuts and then shim the toolholders accordingly. After they were shimmed, with any insert change, they still cut perfectly to size. One tool is set lower and slightly larger than the other. Basically one roughs and the other finishes. With the tool being some much more rigid, the chatter was eliminated and the inserts last forever.

-

I absolutely love the ingenuity of the holder. I wish I had the drive to make my own tools. I just buy them.

-

-

Here's the results. Even in the mini mill, they run smooth and quiet. Typical order is around 600 pcs and the inserts just last and last. I change them about every 1000 pcs if they need it or not.I have machined thousands of these things and the time and effort put forth to make this cutter has paid off many times over.

bryan_machine and cnctoolcat like this.

bryan_machine and cnctoolcat like this. -

Now for a little action. Youtube vid. The tool works wonderfully. I'm running at around 800 SFPM and feeding at 50IPM. They don't always clean up as you can see on the vid(the part on the left). The main thing is that they get machined on at least 50% of the surface. That allows for correct locating in the next operations.

Milling forgings - YouTube -

01-01-2014, 04:30 PM #37

-

So milling the main diameter is just the start of these parts. They then go into the other mill for some more fun. As you can see in this setup, the parts only need to clean up on the areas that are in contact with the step in the stationary jaw.

One quick pass and we have a flat.

And then onto the the 4th. They now need some holes, counterbores and some more milling. With one push of the green button, I get two finished parts. With the first OP(the main diameter) running fairly fast, plus the setup here, these parts can get cranked out in no time. I still hate them with a passion though.

And all finished up.

-

01-06-2014, 07:06 PM #39

Stainless

Stainless

- Join Date

- Jan 2013

- Location

- Gilbert, AZ

- Posts

- 1,039

Nice process!

I have seen those parts before, and I can't for the life of me remember where LOL

So, your qualifying operation, and the flat, are solely for locating purposes huh?

The plates that are welded to the outside of the rotab fixture - are they just to add strength to counter deflection from tightening the set-screws? Were they a fore-thought, or an after-thought? Just curious.-

After thought. She liked to flex a lil too much. Gotta live 'n learn I guess.

- [machinist] Tried and True Machine - Page 2 innovative shop made tooling and fixturing, Lawrence London, 01/07/2014

Archive powered by MHonArc 2.6.24.

Reply

Reply