Read this thread for a diagram for laying out the airy points for supporting your plate...

I

have acquired a 36" square (6" thick) Rahn surface plate. Are the mount

pad locations for a square plate calculated the same as for a

rectangular plate?

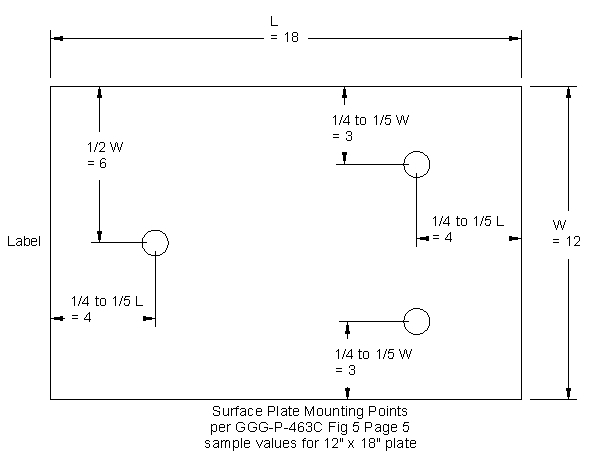

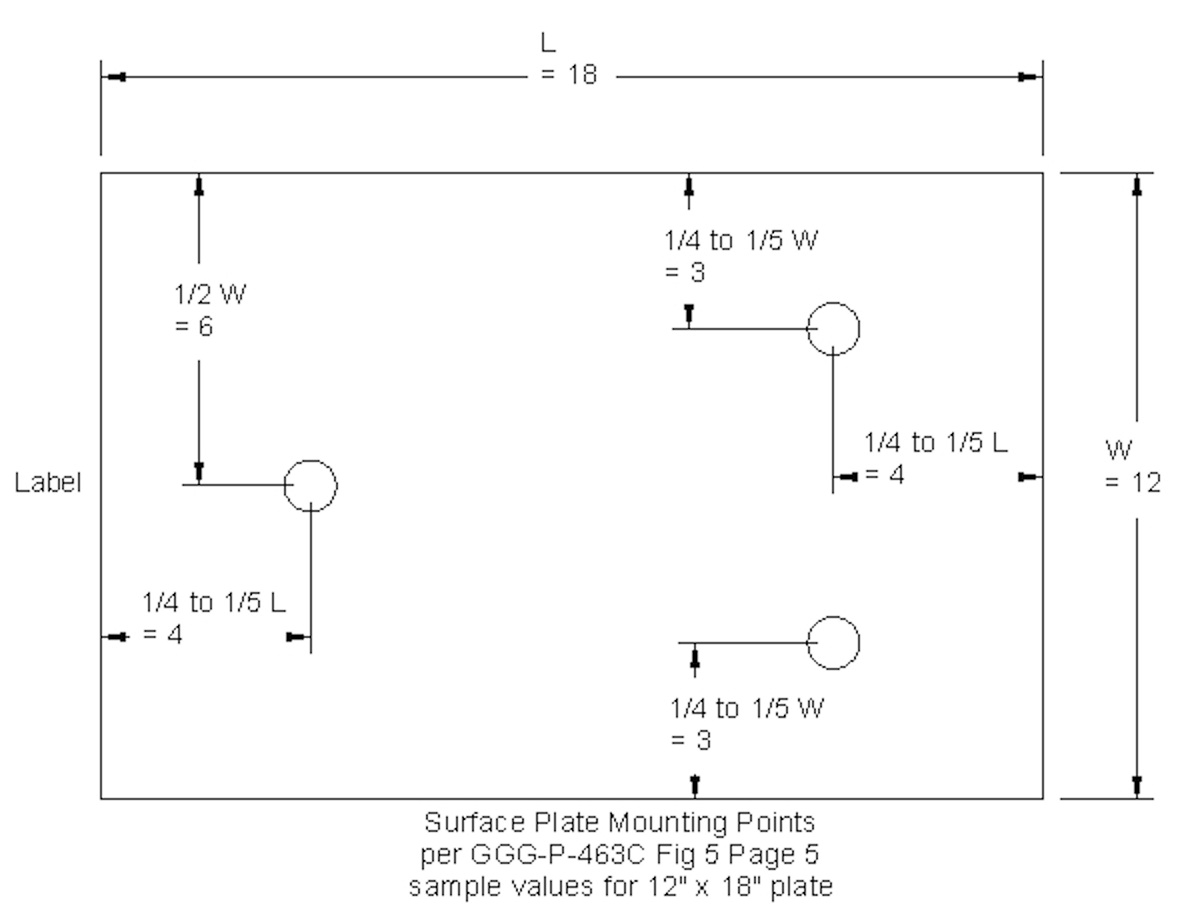

Yes. A square plate is rectangular by definition. The support points are 1/4 to 1/5 of the side dimension.

The mount pads have to be, where they were during inspection and

fine-tuning the inspection plate. Not where you think they should be

(unless you want to repeat final scraping/lapping).

The reason for using three support points at defined locations is to

duplicate the factory environment, so the plate will meet spec.

Surface plates bend, even thick ones. Proper support at defined locations is critical to proper performance.

The mounting points should be marked for you for the reasons that Nick

describes. You probably can't see this marking until you get a good look

underneath. I'm not sure about the really low cost Chinese? granite

plates but others that I have seen have such marking. Small deviations

from these marked positions should not make a measurable difference to

the plate, but if you get them wildly different it could.

Got a chance to look closely at the plate today. It is supported at

three points. Didn't measure but it is a Rahn plate so I suspect they

are correctly located. The plate is coming off the stand when I get it

to the shop. I intend to fab leveling screws at the airy points. Just

as a wag I'd estimate the points are at about the 1/4 distance value.

BTW. I just started a thread looking for surface plate data reduction software.......

Granite surface plate airy points are not important in an unloaded or

lightly loaded surface plate as a specification-meeting plate deflects

an insignificant amount (for all practical purposes) due its own weight

even when "improperly" supported. You will learn this is true if you

read and calculate enough and I tested this out on a plate with a friend

who had very fancy measuring equipment. (Before someone starts

shouting about the fact that EVERYTHING is flexible, please note the

word "practical" in the prior statement.). Airy points do help manage

deflection with significant loading. If you review prior threads, the

appropriate specifications are cited and this whole discussion has been

thoroughly reviewed and debated and reviewed some more.

You want to have your 3 points 1/5 to 1/4 in from the ends. I just had a

frame made for my by tru stone for my 48" x 96" and they used 1/5.

I as well just had to modify the plate for my 72" x 144". I used this

same method. That plate calibrated to within .0008", the guys were

tired and did not want to go more as it was in spec. I have asked them

to come back and it will be interesting to see if it held before they

start again.

A 24' x 36" could easily be supported by a small table or even rolling workbench.

https://www.instagram.com/p/BMEbf1RAWTU/We are modifying the

base for the 72" x 144" granite I bought a while back. The previous

owner had it set up on a 12 point system with jack screws. We are

changing this to the proper 3 point system per the Federal Spec

GGG-P-463c.

I can not find any documation to support the idea to have more points than 3. I know some on @practicalmachinist forum have used 5. But I can find no data on how to space using 5 points.