machinist@lists.ibiblio.org

Subject: Machinist

List archive

- From: Lawrence London <lfljvenaura@gmail.com>

- To: machinist@lists.ibiblio.org

- Subject: [machinist] Workholding Tailstock

- Date: Tue, 22 Oct 2013 14:19:53 -0400

http://www.practicalmachinist.com/vb/general/workholding-tailstock-273855/

-

Workholding Tailstock

Fellas, has anyone knowledge of a tailstock that is or can be equipped with prisms to clamp on round stock?

I’m wondering if I’m alone with the idea that I could put a heavy workpiece on some kind of support on the bed so that I could for example make a center into a 67 lb. piece (30 kg). I have no boring machine but that way I’d go in the direction of one. Tool in spindle

My lathe is a Colchester Master 2500, the short one. If everything fails, I could build myself a tailstock with a low put spindle and possibilities to clamp steel on it, something like the original one upside down. I need to center bigger cuts now. -

Ii have seen four jaw chucks mounted on a MT shank with a bearing so it works as a live center. No reason the bearing could not be welded to stop rotation.

My father had an attachment for a south bend lathe that mounted a vise in place of the toolpost. It had a height adjustment screw. I believe Palmgren made it. the link shows the general idea

Bill D.

Craftsman or Atlas 101 618 6" Lathe Milling Attachment M6 501 | eBay -

I could not quite understand what you want, but I will mention two possibilities.

Schaublin 102 lathes had available a rack and pinion feed tailstock that takes W25 collets instead of a MK2 center or drill shank. Levin and Derbyshire watch lathes also have that type of tailstock available, but for smaller collets. These are very useful tailstocks.

Some lathes have cross slides with T-slots on top. You can remove the compound slide and use the carriage and cross slide as a boring table. Big work pieces can be bolted to the T-slots, with packing to get the desired height. I have done that operation, using a boring bar with an adjustable cutter located in the center of its length, and supported by a live center in the tailstock. It worked very well.

Larry -

10-21-2013, 11:34 AM #4

- Join Date

- Mar 2006

- Location

- Grimsby...UK (a good example of tmesis..unlike Scunthorpe)

- Posts

- 89

Have you tried using a fixed steady...

with the work driven by the chuck and supported by the steady , you'd be able to use the tailstock to drill centres.

The master 2500 fixed steady has a 4.5 ins bore and is quite a sturdy item.

Rob -

10-21-2013, 11:42 AM #5

-

I don’t have a rest, either, unfortunately. But then I only use a three-point steady rest on turned surfaces, not raw stock. Didn’t I kill already some ball bearings with rests?

I have hot rolled construction steel bar cuts, about 4" dia., 20" long (actually 100 mm dia., 500 mm long). One of them weighs 30,8 kg or almost 68 lb. At the moment it’s about giving them a centre but if could do more, I’d make a step forward. My lathe’s spindle has more juice than my mill’s. Bright steel would be nice but not the price.

To avoid frequent change of the upper slide I’m aiming at a tailstock solution. The tailstock is removed from the bed within two seconds. Then the other out the drawer, base cleaned, and on. Matter of a minute, no tools required.

Thank you, Bill, for the link.

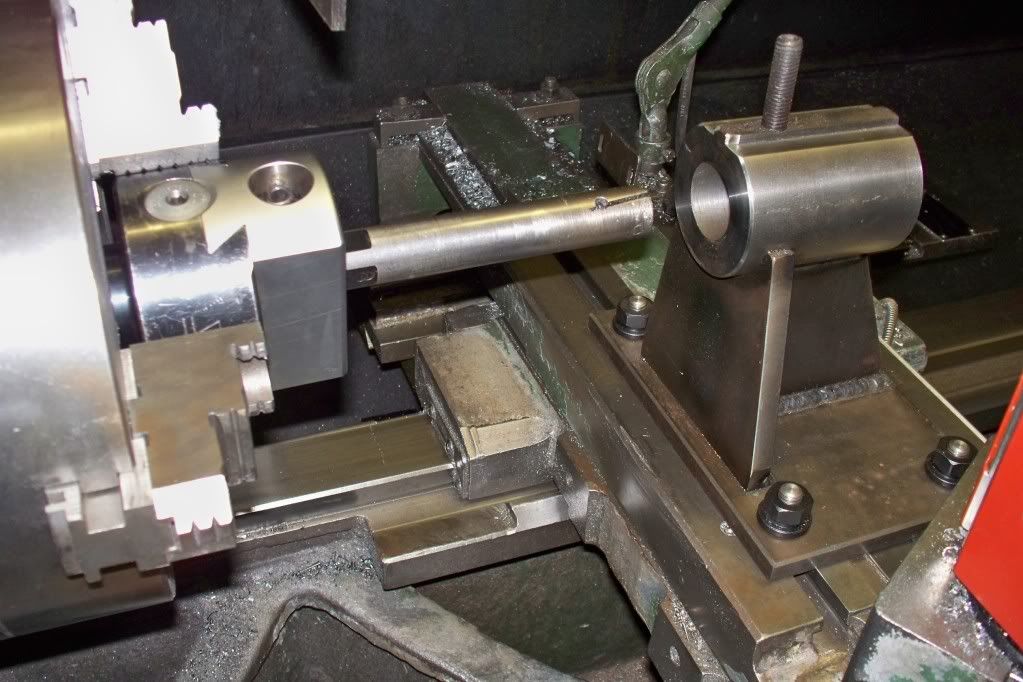

I’ll probably mill me my accessory. If I find another Colchester tailstock, I can cut two or three inches out in height and give it a slide support on top. Connection to quill, case closed. V-prisms, clamp, couple screws. A height adjustment seems to be the one challenge. -

are wou wanting to make the prismatic tailstock contraption because the lathe is not long enough?

-

The usual way to center drill a large bar is to use a drill press or even a hand-held electric drill.

The usual way to center drill a large bar is to use a drill press or even a hand-held electric drill.

You can wrap steel shim stock around a bar and hold it in place with a worm type hose clamp or a twisted wire. Then use a fixed steady with the three jaws riding on the shim stock. I cut the shim stock length to match the circumference of the bar, so there is no step at the place where the ends of the shim stock meet. Shim stock is hard and very smooth. This trick is great to protect a finished part so that the steady jaws do not mar it. But it would also serve to protect the jaws from a rough finish on the bar. If the bar is a little out of round, the center drill will get it running true once it has penetrated the end a little bit.

Larry

- [machinist] Workholding Tailstock, Lawrence London, 10/22/2013

Archive powered by MHonArc 2.6.24.

Reply

Reply